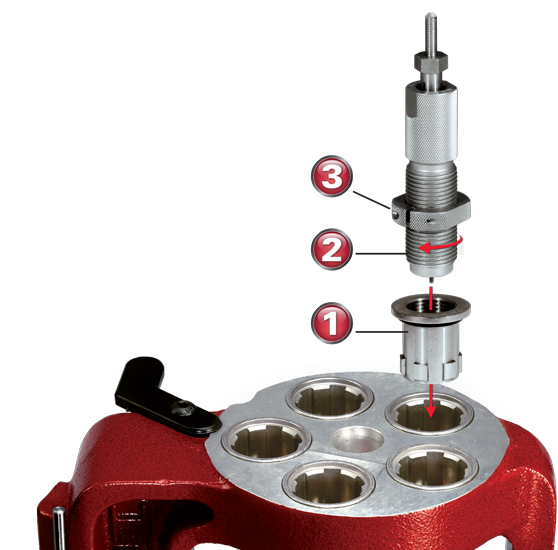

Self-Centering Spindle

Free-floating spindle design ensures precise, concentric neck expansion.

Hornady® Match™ Grade Dies give you total control over neck tension in the resizing process. These dies feature the ability to use interchangeable, self-centering neck size bushings that eliminate the chance of over sizing your case necks and overworking the brass.* Tight tolerances at the press translate into tighter groups at the range. See below for a listing of available dies and bushings.

Available in two styles; full-length sizing and shoulder bump neck size. Both styles utilize interchangeable neck size bushings. Select the bushing your cartridge requires to complete your Match™ Grade Die.

Released in 2024, the Click-Adjust Bullet Seating Micrometer set a new standard in bullet seating. New for 2025, the Click-Adjust Micrometer will now come factory installed on Hornady Match Grade seating dies.

Find Dies See Die Bushings* Bushings sold separately.

Free-floating spindle design ensures precise, concentric neck expansion.

Makes changing neck sizing bushings fast and easy.

Provides slight tension for fine adjustments, and hold setting once in place.

Available in .001" increments, these bushings fully eliminate neck resizing problems. Tight tolerances here translate into tighter groups.

Our Match Grade™ Dies ship with both an elliptical expander and a replaceable decap pin retainer, allowing more versatility for user preference.

The replaceable decap pin is unique to Hornady® Dies.

Measures .001" adjustement for bullet seating depths.

Floating seating stem holds bullet in alignment before the bullet enters the neck of the case.

Choose the caliber you’re reloading and we’ll match it with the proper dies, shell plate, shell holder, trimmer pilot, bullet puller collet, and more.

To change calibers, simply twist the die counterclockwise, remove die and insert your next preset Lock-N-Load® die and bushing. Because they remain locked in their Lock-N-Load® bushings, your dies will remain exactly as you set them. The positive locking action of the Lock-N-Load® bushings holds the dies in rock solid, perfect alignment.