Superformance in Gas Operated Firearms

Background

Superformance ammunition was developed in the Hornady ballistics lab utilizing state of the art test equipment in accordance with SAAMI (Sporting Arms and Ammunition Manufacturers Institute) guidelines for pressure, velocity and accuracy utilizing test barrels with SAAMI minimum specification chambers and bore and groove dimensions.

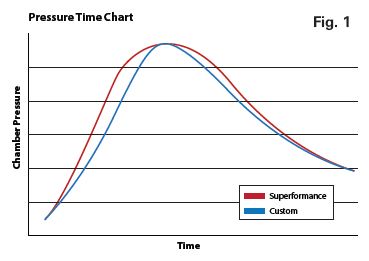

Superformance propellants provide a longer duration/application of peak pressure in the pressure time curve that occurs within the barrel (see Fig. 1 pressure curve). In other words, both Superformance and standard propellants provide an equally powerful “push” applied to the base of the bullet, but with Superformance propellants, the “push” is applied for a longer period of time.

Once the peak pressure dissipates, the Superformance powder burn returns to a “normal” curve, similar to standard propellants. This illustrates the highly progressive burning characteristics of the powder and its ability to completely burn. A complete burn of the entire Superformance charge takes place in a shorter period of time, creating far less velocity reduction in shorter barrel lengths (barrel length = time to burn).

Internal Ballistics of Superformance in Semi-Auto / Select Fire Guns

Superformance ammunition is tested and is safely within SAAMI pressure guidelines. Gas operated (direct impingement or gas piston) firearms are perfectly safe to use with Superformance ammunition. However, Hornady ballisticians have conducted testing with a variety of guns (including guns equipped with suppressors), and our findings conclude that some systems work far better with Superformance ammunition than others.

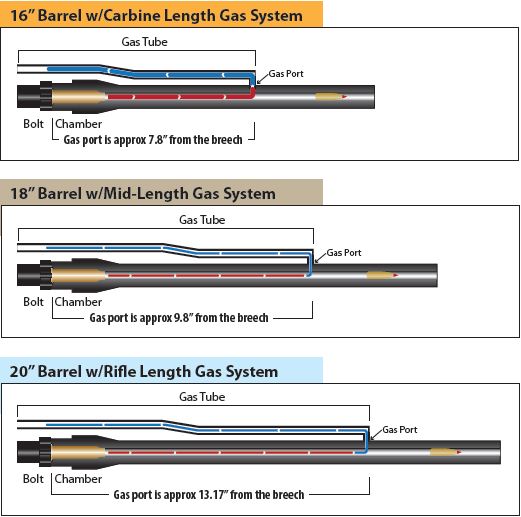

It is recommended that to get the best functioning with Superformance ammunition in gas operated/gas piston semi-automatic or select fire guns, rifle length gas systems with 20 inch or longer barrel lengths are best for reliable firing and extraction. Any other configuration, particularly shorter barrels/gas systems are best served with the installation of an adjustable gas system, ESPECIALLY if a suppressor is to be installed.

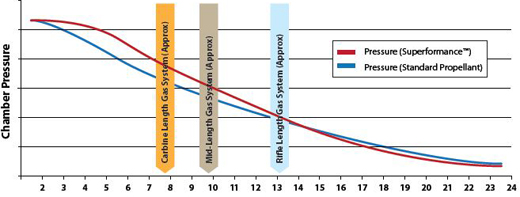

Due to the longer duration of peak pressure produced by Superformance™, the post peak/declining port pressure at common carbine and mid-length gas port locations is still higher than that produced by standard propellant. This has a tendency to flood the system with a larger volume of gas, at a higher velocity, that tries to open the bolt of the gun too fast. It’s a timing issue. The cartridge case is still swollen from the application of pressure during firing while the gun is simultaneously trying to extract the cartridge case before it has had an opportunity to settle back to its original size, or more simply: the gun is still in the process or firing while it’s trying to extract the cartridge case.

If the firearm and the ammunition are not in sync, there can be what is commonly identified as “pressure signs” on the cartridge case. This is exhibited by the movement/marring of the head of the cartridge case, cratered primers, flat primers, ripped or ruptured cartridge cases, “popped primers”, and/or any combination of these effects. If any of these “pressure signs” are apparent, stop firing immediately. If an adjustable gas system is installed, it is advisable to reduce the amount of gas flowing through the system by closing the gas port until the gun operates correctly.

With the installation of an adjustable gas system, gas pressure can be metered to a point that enough gas is applied to open the bolt, but at a slower rate to allow the cartridge case to return to its original diameter prior to the movement of the bolt, and thus allow for proper extraction.

Pressure VS Gas Port Location

Due to the longer duration of peak pressure produced by Superformance™, the post peak/declining pressure at common carbine and mid-length gas port locations is still higher than that produced by standard propellant. However, there is very little difference in port pressure between Superformance™ and standard propellants at the rifle length port location.

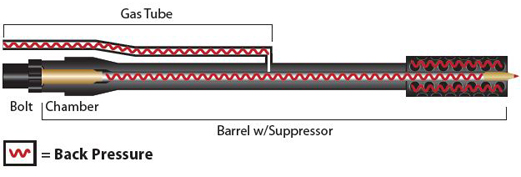

Superformance and Suppressors

The use of suppressors on rifles creates yet another dynamic in firearms design that is not commonly understood or communicated. Consider the suppressor on a firearm the same as a muffler on a car. The suppressor works as a filter for the gas (noise) that is escaping the barrel during firing. As a “filter”, it takes longer for the gas to leave the confines of the firearm, and thus, it creates back pressure. This back pressure, ESPECIALLY in a gas operated firearm forces an extensive amount of gas back through the firearm’s operating system that may create too much thrust too early during the firearm’s cycle of operation.

To counteract this back pressure, the use of an adjustable gas system is advised. By metering the gas system to ensure that it will cycle the firearm correctly and not flood the system with gas/pressure, the gun will work properly and will still benefit dramatically from the increased velocity potential of Superformance ammunition.

Back Pressure from Suppressor

Click here to download this as a PDF.