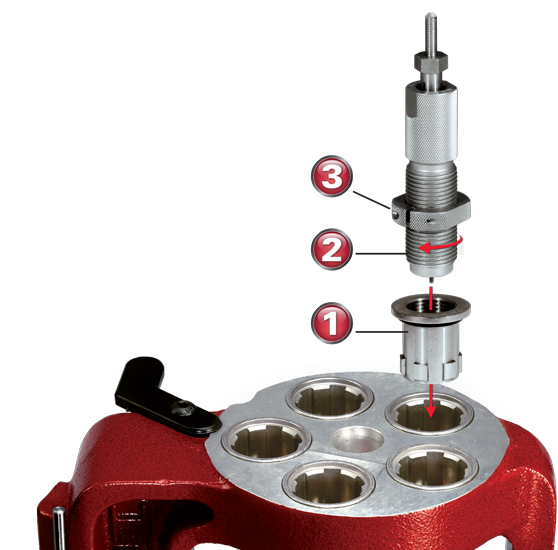

Zip Spindle™ Design

A feature on all full length size dies, the Zip Spindle™ positively locks to eliminate slippage. A series of light threads cut on both the spindle and spindle collet allows incremental adjustments by turning the spindle or it can easily “zip” up or down for larger movements.